As you explore options for your new home, consider the rising trend of metal building homes. They stand out for their durability and energy efficiency.

The use of steel frames in residential construction brings a mix of quality and cost savings that traditional materials often cannot match.

You will find that these homes offer more than strength; they embody flexibility in design. You can choose from a range of styles, from classic to modern, making your home truly yours.

With metal homes, you also benefit from reduced maintenance, which adds to the long-term affordability.

Customize your home to suit your lifestyle without breaking the bank.

Metal homes provide an affordable path to homeownership with the added advantage of personalizing your space to fit your tastes and needs.

Enjoy the process of crafting a home that reflects your preferences while securing a space built to last.

1. What Are Metal Building Homes?

Metal building homes represent a modern solution in residential construction that combines durability and versatility.

These homes typically feature steel frames and innovative designs suited for contemporary living.

Defining Metal Building Homes

Metal building homes refer to residential structures made primarily of steel, a material known for its strength and longevity.

Unlike traditional homes, they often incorporate a steel frame that provides a robust and solid foundation.

The steel construction not only ensures stability but also offers resistance to weather elements, pests, and fire.

The term metal homes captures a variety of designs, from the classic Quonset huts with their distinctive arch shapes to modern steel frame homes that mimic traditional architecture.

History and Evolution

The concept of metal homes has evolved from the early quonset huts, first introduced during World War II for their quick assembly and portability.

Post-war, the adaptability of these steel structures saw them repurposed for residential use.

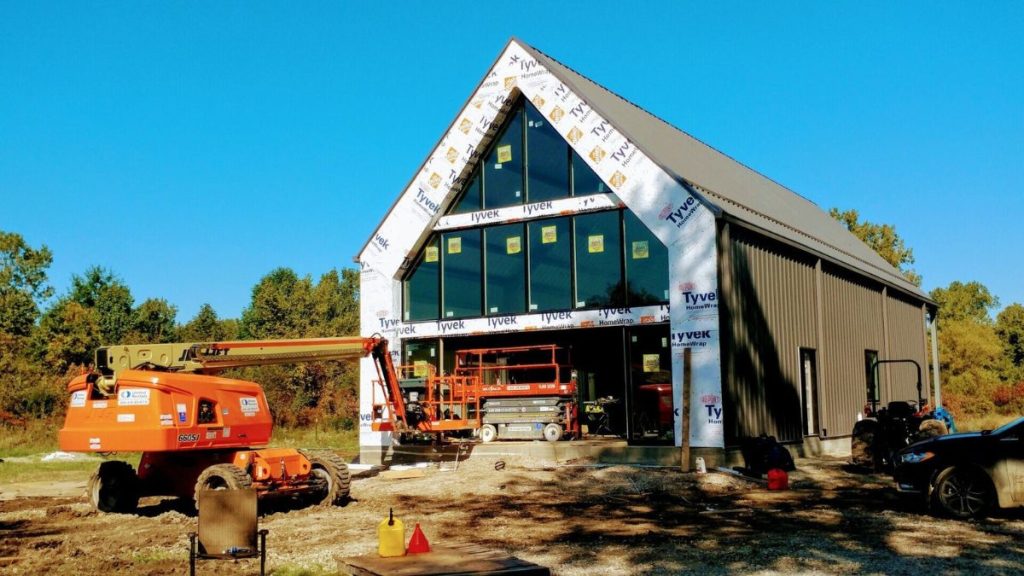

Steel building homes have since advanced, incorporating pole barn techniques and the increasingly popular barndominium—a portmanteau combining ‘barn’ and ‘condominium’.

These trends showcase the evolution of metal homes that blend classic aesthetics with the practical benefits of steel construction.

Common Types

The common types of metal building homes include:

- Barndominiums: Now a catch-all term for a barn-like residential structure, these steel homes provide open, adaptable spaces, often with high ceilings and open beams.

- Steel frame homes: These homes put a modern twist on traditional designs using a steel skeleton that can adapt to virtually any floor plan.

- Quonset huts: Recognized by their semi-circular shape, these lightweight steel buildings offer simplicity and cost-effectiveness.

- Pole barns: Not always made entirely of metal, these usually incorporate a wooden pole frame with metal siding, known for their spacious interiors and versatile use.

2. Benefits of Metal Building Homes

Metal building homes offer durability, cost savings, enhanced safety, and energy efficiency. Explore the advantages that might make them a solid choice for your dwelling.

Durability and Maintenance

Your metal home stands up to severe weather, resisting damage from wind, rain, and snow. Robust construction demands less maintenance, freeing up your time and saving you money in the long term.

Cost-Effectiveness

From construction to long-term ownership, metal buildings prove kind to your wallet.

They typically cost less to build than traditional homes and offer structural warranties, ensuring quality without breaking the bank. Additionally, potential financing options can ease the initial investment.

Safety Features

Strong and resilient metal homes protect you from fire hazards due to their non-combustible nature. They also boast strong secondary framing, adding an extra layer of safety for you and your loved ones.

Energy Efficiency

Insulation innovations mean your metal home stays cool in summer, warm in winter, and dry all the time. These homes often exceed standard energy codes, resulting in lower utility bills and a comfortable living space year-round.

3. Design and Customization Options

Metal building homes offer a range of design options to make your house stand out. You choose the materials, styles, and layout to create a unique space that reflects your personal taste.

Material and Style Selection

When selecting materials for your metal home, you can pick from various metal panels and trims. Exterior finishes like wainscot and different paint colors allow for unique customizations.

You can design the roof to match your style, whether that’s a classic gable or a modern mono-pitch.

- Roof Styles: Gable, Hip, Flat, Mono-pitch

- Exterior Finish: Wainscot options, color choices

- Trim: Customizable color and style

Interior Design Flexibility

Your metal home’s interior is a blank canvas. Install large windows or skylights to let in natural light.

Select doors that complement your home’s decor and don’t worry about load-bearing walls, which gives freedom for an open floor plan.

- Doors: Numerous styles and sizes

- Windows and Skylights: Custom placements for natural light

- Space: Open layouts without the need for load-bearing walls

Layouts and Floor Plans

Choosing a floor plan involves more than just the number of bedrooms. Customize your metal building home with a range of floor plan options.

Decide on a cozy two-bedroom or expand to a larger family home. Incorporate unique spaces like a workshop or a home office to fit your lifestyle.

- Small Home: 35×50 two-bedroom

- Family Home: Multiple bedrooms, bathrooms

- Custom Spaces: Workshops, offices, extra storage

4. Costs and Considerations

Before diving into the world of metal homes, you need to grasp the costs you may encounter and some factors that change these numbers. You also should know about any possible downsides.

Typical Price Ranges

Metal building homes offer a broad price range due to their customizable nature. For the shell alone, you might pay $5,000 – $30,000 if you own the land and opt for a smaller footprint.

Yet, a more typical estimate for a full build averages around $359,228 with all construction, land, and finishings included.

Metal homes can cost a less eye-watering $50 – $65 per square foot compared to traditional builds that might set you back $100 – $150 per square foot.

Factors Affecting Costs

Many elements affect the price tag:

- Steel Building Kit: Metal home kits range from $10 – $25 per square foot.

- Size and Design: Larger homes with complex designs cost more.

- Finishing Touches: High-end interiors can drive up the cost.

- Labor: Includes assembly and construction fees.

- Land: If you don’t own it, purchasing land adds a significant amount.

- Local Codes: Meet local building requirements can affect material choice and cost.

Limitations or Downsides to Consider

Despite the lure of affordability, metal homes come with their own set of drawbacks:

- Financing: Finding a loan for a metal home poses more challenges. Lenders are less familiar with these builds, making financing more complex.

- Resale Value: Metal homes may attract fewer buyers, affecting resale.

- Local Codes: In some areas, metal homes must meet strict codes that could limit your design or increase costs.

Understand these costs and considerations to ensure no surprises catch you off guard in your metal home adventure.

5. Construction Process

When you embark on constructing a metal building home, two major steps define the journey: preparing the site and assembling the structure.

Site Preparation

Before the actual building starts, you need to prepare the land. This involves clearing the debris and leveling the ground.

You’ll pour a concrete slab, which will serve as a stable foundation for your metal building. This slab must match the dimensions of your building design to ensure proper fit and structural integrity.

Assembling the Structure

Once the foundation sets, you initiate the assembly of your metal building kit. Typically, these kits come with prefabricated steel frames which form the backbone of your home.

You’ll erect these frames, align and secure them properly to form the skeleton of the structure. It’s crucial to handle each piece with care to maintain the integrity of the steel construction.

6. Uses for Metal Buildings

Metal buildings offer durability and versatility, making them ideal for various applications. From residential homes to commercial spaces, the potential uses meet a wide range of needs.

Residential Applications

Your dream home could take the shape of a metal building home or a barndominium. Steel buildings provide a functional and durable living space that requires less maintenance than traditional stick-built homes.

With their flexibility, you can design a home that suits your taste and stands the test of time.

Commercial and Agricultural Uses

For your business, steel buildings adapt to serve as offices, retail spaces, or warehouses. They suit the agricultural sector well for barns and storage facilities due to their robust structure and functional design.

Examples: Retail shops, Offices, Barns.

Storage and Workshops

Whether you need space for personal storage or a large workshop, metal buildings can meet your needs. They provide a secure and durable place to work on projects or store goods and equipment.