Rubberwood is an intriguing material that has been gaining popularity in furniture making.

This versatile hardwood comes from the Hevea brasiliensis, or rubber tree, which is the same tree that produces natural latex.

When the tree reaches the end of its latex production life, the wood is harvested and used to create various products, including furniture.

As you delve into the world of rubberwood, you’ll discover that it has several advantages, such as being sustainable, cost-effective, and easy to work with.

However, like any material, it has its fair share of disadvantages, including potential warping, twisting, and allergen concerns.

1. What is Rubberwood?

Rubberwood, known as Hevea brasiliensis or the Pará rubber tree, is a light-colored, medium-density tropical hardwood.

This versatile wood is obtained from rubber trees, which thrive in plantations across Asia, Africa, and America.

These trees typically grow between 100-130 feet tall and can live up to 100 years.

When working with rubberwood, you’ll notice its beautiful, natural appearance, perfect for crafting furniture and wood accessories.

Plus, it’s an environmentally friendly wood; plantation trees that have already served a useful purpose are reused, making rubberwood a sustainable choice.

So why is rubberwood so popular? One reason is that it’s an affordable alternative to medium-density fiberboard (MDF) and other engineered wood products.

Rubberwood has a real wood feel, making it a great choice for products like shoe racks and children’s bunk beds.

Professional woodworkers also appreciate its good value, similar to that of pine.

Just remember, like with any material, rubberwood has a few disadvantages. It is perishable and may trigger allergies in some individuals.

Additionally, it’s not recommended for outdoor use due to its perishability.

However, these drawbacks shouldn’t discourage you from exploring rubberwood as a sustainable and versatile option for your woodworking projects.

READ MORE: 15 Most Common Types of Wood for Furniture

2. Advantages of Rubberwood

Affordability

One of the advantages of rubberwood is its affordability. It is a cost-effective option for your woodworking projects, making it attractive if you’re on a budget.

This hardwood offers a good balance between quality and price, providing a durable and beautiful material at a reasonable cost.

Durability and Quality

When it comes to durability and quality, rubberwood doesn’t disappoint. It is a stable, strong, durable hardwood with a Janka hardness of around 500 pounds.

Its strength is approximately 9500 psi, and its stiffness measures 1.3 million PSI, making it a suitable choice for furniture and interior millwork.

Visual Appeal

Rubberwood has a beautiful grain pattern that visually appeals to your woodworking projects. The wood is light in color, making it ideal for staining or painting to achieve the desired look.

Its attractive grain patterns can enhance the appearance of furniture, cabinetry, and other wood accessories you create with rubberwood.

Versatility in Woodworking

Rubberwood is versatile and easy to work with, making it a favorite among furniture makers, woodworkers, and artisans.

Its ease of use allows for various woodworking techniques such as joinery, millwork, and cabinetry.

Moreover, rubberwood is suitable for indoor use and often produces medium-density fiberboard (MDF) for interior applications.

Environmental Sustainability

Another advantage of rubberwood is its environmentally friendly nature. This sustainable hardwood comes from the Pará rubber tree (Hevea brasiliensis), typically grown in rubber plantations.

Once these trees are no longer productive for latex extraction, they are harvested and repurposed for wood production, making rubberwood an eco-friendly choice and contributing to a lower carbon footprint.

READ MORE: Cheapest Wood for Furniture

3. Disadvantages of Rubberwood

Vulnerability to Damage

Rubberwood, like any other wood, has its drawbacks. Due to its high moisture content, it is prone to warping, twisting, and cracking.

When the wood dries, the moisture evaporates, causing changes to its shape. To reduce these issues, it’s crucial to properly season and treat the wood before using it in your projects.

Additionally, rubberwood’s susceptibility to decay and damage makes it less ideal for outdoor use. Moisture, fungi, and insect attacks can deteriorate the wood.

If you plan to use rubberwood for an outdoor project, it’s essential to treat it with proper sealants, and even then, be prepared for possible problems down the line.

Possible Allergic Reactions

The tree produces latex, the primary source of natural rubber. This can be a disadvantage for those who are allergic to latex.

While the latex content is low in rubberwood, it may still trigger allergic reactions in sensitive individuals.

When working with rubberwood, take the necessary precautions, like wearing gloves and a mask if you have a latex allergy.

Importantly, if you’re building furniture for others, always inform them of the materials used to prevent potential allergy-related issues.

Insect and Fungal Attacks

Rubberwood’s vulnerability extends to various pests, such as insects and fungi. Insects like termites, beetles, and borers can burrow into the wood and cause significant damage.

Fungi can cause decay and weaken the wood structure over time.

To protect your rubberwood projects from these threats, here are some prevention tips:

- Store the wood in a dry, well-ventilated area.

- Use a wood preservative to protect against fungi and insects.

- Regularly check for signs of damage and address them promptly.

READ MORE: Best Online Used Furniture Stores in The USA

4. Rubberwood Uses in Furniture and Construction

Furniture

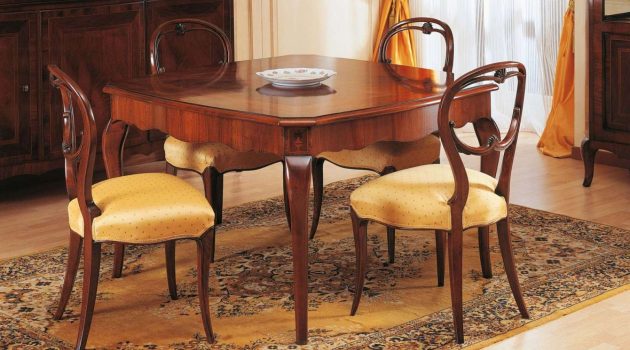

Rubberwood has found its way into producing various furniture pieces thanks to its durability and affordability.

Its light and attractive color makes it widely used for chairs, desks, and solid wood furniture, blending well with various interior designs.

However, due to its perishable nature, there are better choices for outdoor furniture.

Remember that if untreated, rubberwood can be prone to rotting, so it’s vital to ensure proper treatment and care.

Millwork and Joinery

Rubberwood’s dense grain and adaptability make it ideal for millwork and joinery.

Its ability to take stains well and retain their shape contributes to its popularity in kitchen accessories, cabinets, and other intricate woodworking projects.

In addition, its easy-to-work-with nature makes it a favorite for many craftsmen.

Flooring

Since rubberwood is naturally resistant to heat, it’s a suitable option for flooring. However, remember that there are more resilient options compared to other hardwoods.

Its lighter color may differ from everyone’s preference, but it can contribute to your space’s bright and clean aesthetic if that is what you want.

Construction

In construction, rubberwood finds use in the form of plywood and veneers. Thanks to its cost-effectiveness and sustainability, it provides an eco-friendly alternative to traditional materials.

Although it may not be the top choice for every construction need, it certainly has its place as a viable option in specific applications.

READ MORE: How to Pick the Right Furniture

5. Comparison to Other Woods

Teak vs Rubberwood

- Appearance: Teak is known for its rich golden-brown color, while rubberwood has a lighter, more neutral tone. Teak’s natural oils give it a more polished look, while rubberwood has a more matte finish.

- Durability: Teak is an incredibly strong and durable wood, making it a popular choice for outdoor furniture. Rubberwood, while also strong, may not be as suitable for outdoor use due to its perishable nature.

- Cost: Teak is often more expensive than rubberwood, primarily due to its demand and limited availability. Rubberwood, on the other hand, is a more budget-friendly option.

Maple vs Rubberwood

- Hardness: Maple wood is a denser, harder wood compared to rubberwood, making it a better choice for furniture that requires more support, such as chairs or tabletops.

- Workability: Both maple and rubberwood are easy to work with, but rubberwood takes stains and finishes slightly better than maple.

- Sustainability: While maple is a sustainable wood, rubberwood is considered more eco-friendly, as it is sourced from trees that have completed their latex production cycle.

Ash vs Rubberwood

- Grain Pattern: Ash has a more pronounced and unique grain pattern compared to rubberwood’s subtle and consistent grain. This can make ash wood more visually appealing for certain applications.

- Strength: Ash is stronger and more flexible than rubberwood, making it an excellent choice for furniture frames and other applications that require the wood to bend without breaking.

- Cost: Ash wood typically falls in between rubberwood and teak in terms of cost, making it a middle-of-the-road option when it comes to price.

6. Maintenance and Care of Rubberwood Furniture

Rubberwood furniture is a popular choice due to its affordability and sustainability.

To ensure the longevity and beauty of your rubberwood pieces, it’s essential to commit to proper maintenance and care.

Following these friendly tips lets you keep your rubberwood furniture in great condition.

Cleaning

Regular cleaning is necessary to prevent the accumulation of dust and dirt. Use a soft, damp cloth to wipe down your rubberwood furniture.

Avoid harsh chemicals or abrasive cleaners, which can damage the wood’s surface. Stick to gentle, wood-friendly cleaning products if needed.

Finishes

One of the advantages of rubberwood is that it takes stains and finishes well. Applying a finish helps protect the wood from damage and enhances its natural beauty.

Choose from various finishes, such as varnish, lacquer, or oil, based on your desired look and protection level.

Refinishing

You may notice some wear and tear on your rubberwood furniture over time. Refinishing is an option to restore its original appearance.

Gently sand away any scratches or imperfections, then apply a fresh coat of your chosen finish. Always follow the manufacturer’s guidelines for drying times and use proper safety measures.

Kiln Drying and Chemical Treatments

Rubberwood is often treated with chemical preservatives and undergoes a kiln-drying process to improve its durability.

Kiln drying removes excess moisture, reducing the risk of warping or cracking, while chemical treatments help protect against pests and fungi.

Make sure any rubberwood furniture you purchase has undergone these essential treatments.

Waterproofing

Rubberwood is not naturally waterproof, so protecting it from water damage is important.

Use coasters, mats, and other protective barriers under cups, dishes, and vases to prevent moisture from seeping into the wood. In the case of any spills, quickly wipe them up with a soft, dry cloth.

By following these simple maintenance and care tips, you can enjoy the beauty and functionality of your rubberwood furniture for years to come.

Remember to clean gently, choose appropriate finishes, and protect your pieces from moisture and damage.

Frequently Asked Questions

What are the pros and cons of rubber wood compared to other types of wood?

Rubberwood has several advantages such as being cost-effective, durable, and environmentally friendly. It is easy to work with and takes stains well. Some disadvantages include being perishable, potentially triggering allergies, and not being suitable for outdoor use.

How does rubber wood hold up against termites?

Rubberwood is not naturally resistant to termites, but it can be treated with chemicals to enhance its resistance. For areas prone to termite infestations, it is recommended to treat rubberwood furniture or use a more termite-resistant wood type.

What are the differences between rubber wood and plywood?

Rubberwood is a type of hardwood sourced from rubber trees, while plywood is made by gluing together thin layers of wood, called plies. Rubberwood is more durable and offers a more natural, solid look, whereas plywood is lighter and less expensive but may not be as aesthetically pleasing.

How does rubber wood compare to pine wood?

Rubberwood is generally more durable and harder than pine wood. Both woods possess relatively simple textures and can be stained easily. Pine is more readily available, making it generally cheaper than rubberwood. Each wood type has its own distinct appearance, with pine wood typically showing more knots and grain patterns.

What factors affect rubber wood pricing?

Rubber wood pricing can be affected by factors such as demand, availability, transportation costs, and processing methods. Prices may also vary based on the furniture piece and how it is finished or assembled.

What is the durability of rubber wood furniture?

Rubberwood is a durable hardwood, comparable to maple in terms of strength and hardness. When properly cared for and maintained, rubberwood furniture can last for many years. However, it is not ideal for outdoor use, and exposure to the elements can significantly reduce its lifespan.